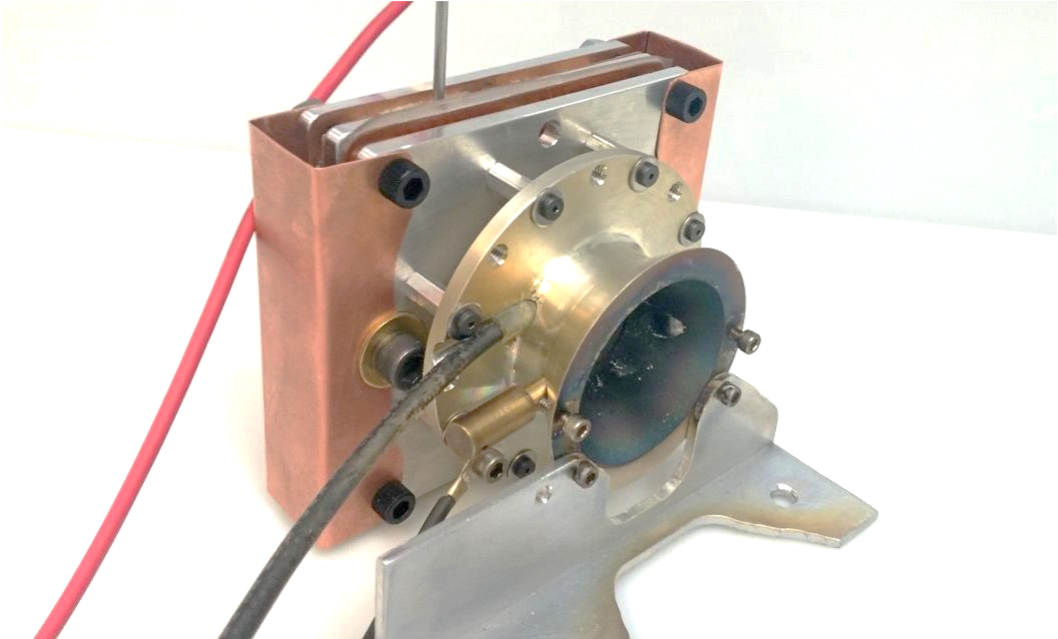

We have developed a patented Fiber Feed Pulsed Plasma Thruster (FPPT) that consumes PTFE propellant from spooled foam. Thrusters use massively parallel processing in the design of energy storage units (ESUs) to assemble COTS components into separate modular capacitor assemblies while keeping specific current levels low per cap. Discharge initiation is via a regenerated carbon igniter array located at the thruster cathode. Thruster performance depends on fuel supply, with measurements in 16 JESU configurations ranging from 0.12mN-s @ 1,000s to 0.09mN-s @ 1,700s. A higher specific impulse of 2400 seconds was measured in the 32J configuration. The 1U design provides a total impulse of up to 5,500 Ns, and the 1.7U design provides a total impulse of up to 15,000 Ns. Accelerated subsystem life tests showed> 1. 6 billion capacitor charge / discharge cycles with nearly identical specific current waveforms. FPPT uses a completely non-toxic solid propellant, Teflon, with mild exhaust, no corrosive or propellant clogging issues, and on-demand thrust with no warm-up time required. .. In addition, the ability to control both the input power and the propellant feed rate allows adjustment from high Isp operation to high thrust operation. CUA believes that FPPT technology is a compelling option to meet many micropropulsion needs, including deep space missions. The ability to control both the input power and the propellant feed rate allows adjustment from high Isp operation to high thrust operation. CUA believes that FPPT technology is a compelling option to meet many micropropulsion needs, including deep space missions. The ability to control both the input power and the propellant feed rate allows adjustment from high Isp operation to high thrust operation. CUA believes that FPPT technology is a compelling option to meet many micropropulsion needs, including deep space missions.